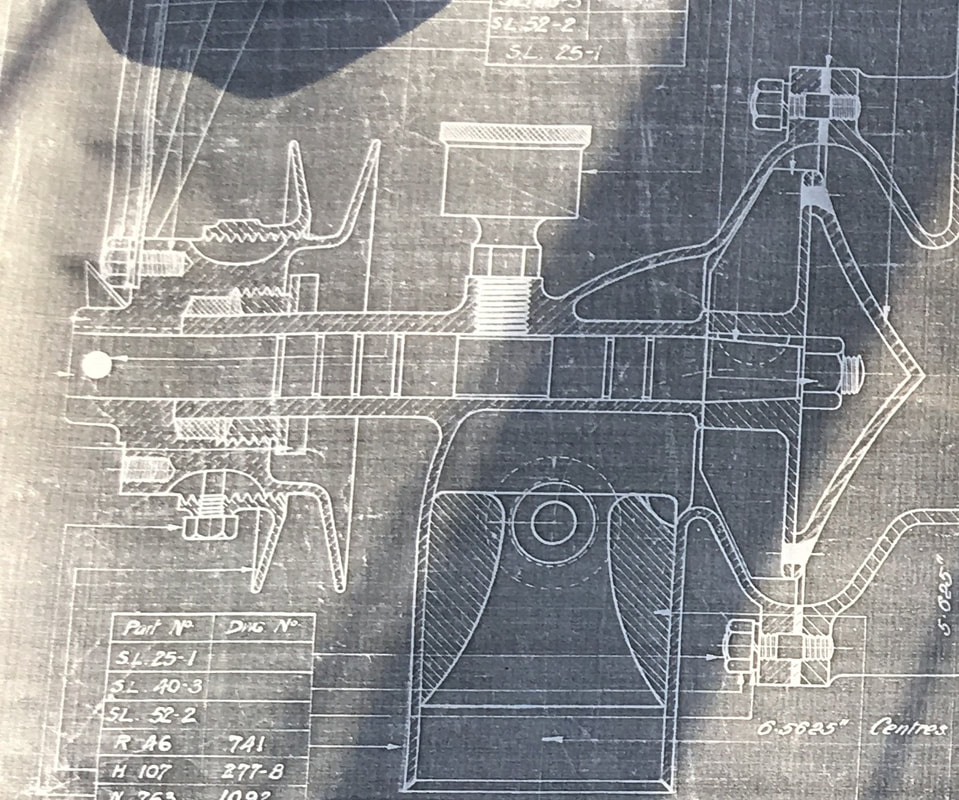

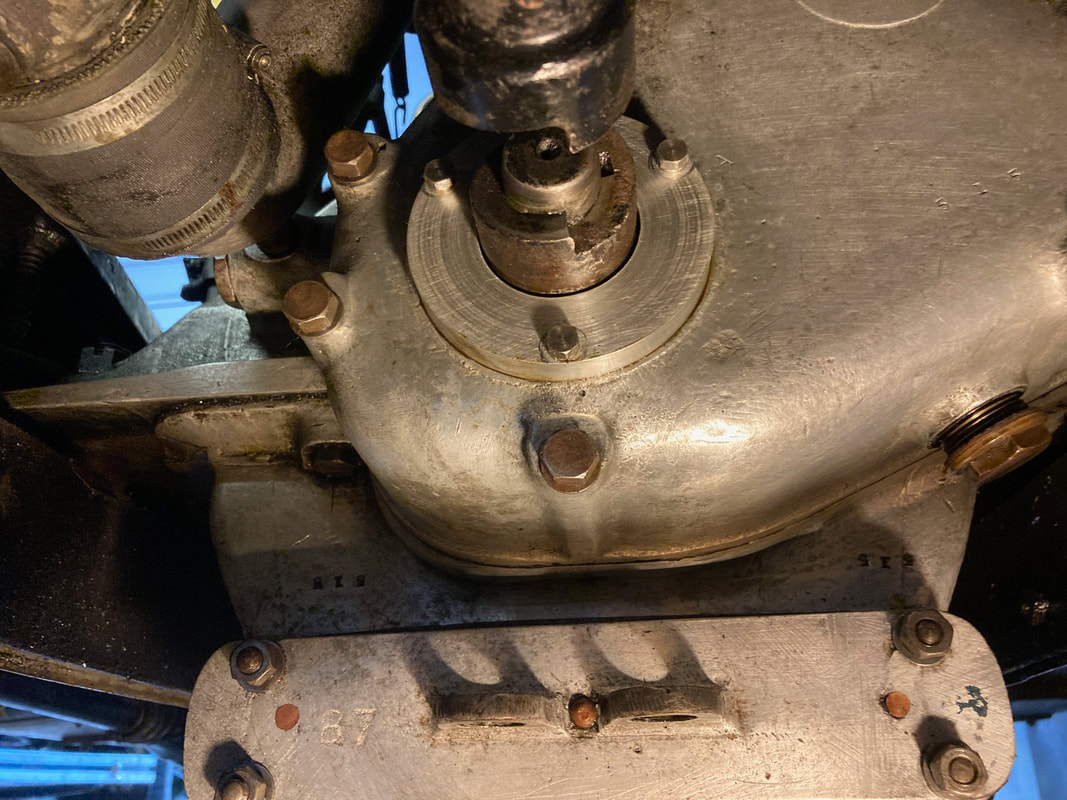

E type Water Pump

Assembly drawing

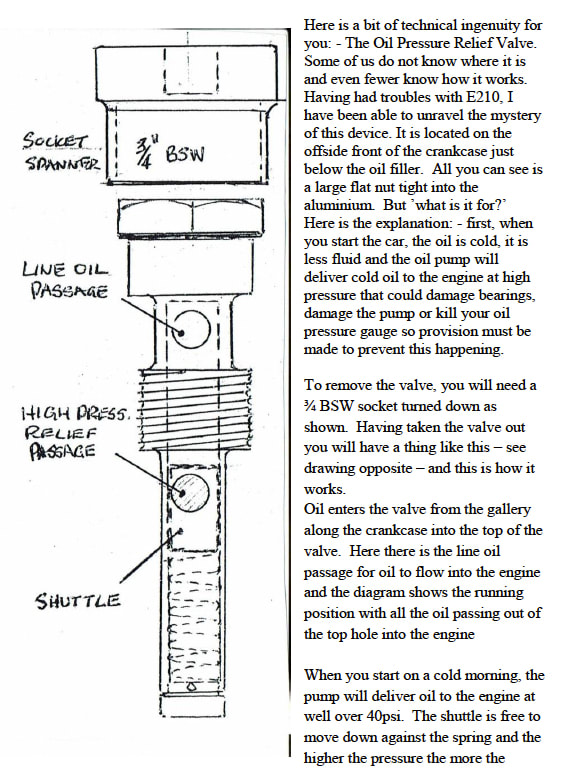

Oil Pressure Relief Valve

From Mr Archer's notes: Located externally low down, on right side front of crankcase, common to all models. It consists basically of a plunger sliding in a tube. It is opposed by a spring, if the oil pressure rises to beyond a certain pressure, the plunger compresses the spring to the point where it uncovers the outlet port, allowing the oil to discharge through a spout onto the timing chain. Because of the pulsating nature of the output of the plunger pump, this oil valve tends to vibrate in sympathy causing wear, this often gets to the point where oil simply passes straight through. The valves are best reconditioned by fitting a new working body to the existing hexagonal plug portion. The sliding plunger valve is replaced by a 45° angle conical seated valve. A new adjustable spring completes the job. The assembly being tested in the rig to 30 PSI.

From the 30-98 Newsletter Oct '16:

|

From Paul Rogers: Use a machine reamer (which has a morse taper) to ream out the hole that the shuttle slides in. A machine reamer is the same diameter along its length where as a hand reamer has a tapered lead-in so is no good for blind holes.

Then remake the shuttle so that it has just enough clearance to fall down the bore under gravity. Use steel for the shuttle (the same as the bore) as they'll expand at the same rate. Other metals (eg aluminium or brass) will expand at a quicker rate, jamming it. New parts are available - contact: Paul Rogers Engineering |

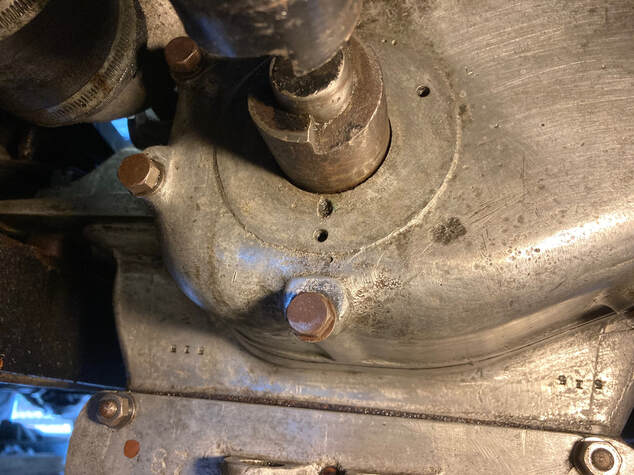

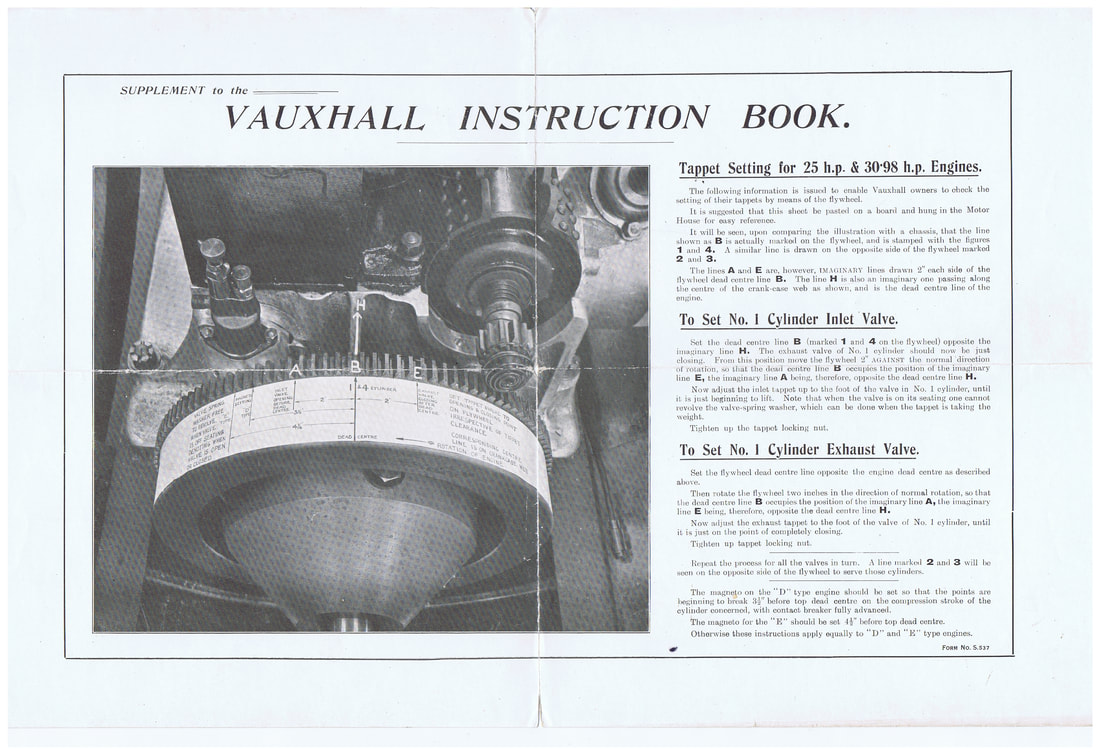

Timing Cover Oil Seal leaks

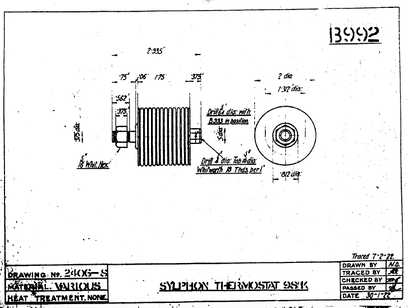

Thermostat: OE & OD

|

Replacement bellows: If you can find one, a suitable replacement bellows is VW part number 111 119 159A, as fitted to (air cooled) VW Beetle 1961-2003 VW T2 Split 1961-1967 VW. See images right.

|

The original E type side valve engine had no thermostat, however they were fitted to all the overhead valve OD and OE models. Not only does this control the temperature of the engine, it also slows down the rate of circulation of the coolant, eliminating the loss of coolant down the overflow pipe at higher engine speeds, as the radiator core sometimes seems unable to cope with the flow from the pump.

The original unit consist of a Sylphon bellows (made by The Fulton Co), a valve, and a rod linking the two. A drawing of the original bellows is shown left. |

If the valve is missing, an option is to have a brass adaptor made to suit the internal diameter of the top hose, and use a 'modern' bellows type thermostat soldered to it. Or better, contact Crank Start Engineering in Victoria, who can supply replacement valves, or complete assemblies if required:

https://crankstartengineering.com/contact.aspx

John Kent/DK Feb '21

If the valve is missing, an option is to have a brass adaptor made to suit the internal diameter of the top hose, and use a 'modern' bellows type thermostat soldered to it. Or better, contact Crank Start Engineering in Victoria, who can supply replacement valves, or complete assemblies if required:

https://crankstartengineering.com/contact.aspx

John Kent/DK Feb '21

Exhaust Manifolds

|

Both E and OE models have steel exhaust manifolds. Blocks and heads are cast iron. The manifold, being thin steel, expands much quicker than cast iron. To allow for expansion, file the holes into horizontal slots on cylinders 1&4 (and 2&3 if you're feeling enthusiastic). Fit using plain (flat) washers with spring washers and brass nuts. When tightening, make sure the spring washer isn't completely flattened, indicating that there isn't a vast amount of clamping force.

On this head, right, the failure is very old, as is the attempt at welding it, which held for another 20 or so years. Fatigue in use finally snapped it again. Given such a thin wall there was no option but to buy a new head.......... The lack of tightness might mean that the gasket 'puffs' a bit until it's warm, but which would you prefer? Image and Info: Paul Rogers Apr '21 |